Exploring the Future of 3D Printing with DLP Resin Technology

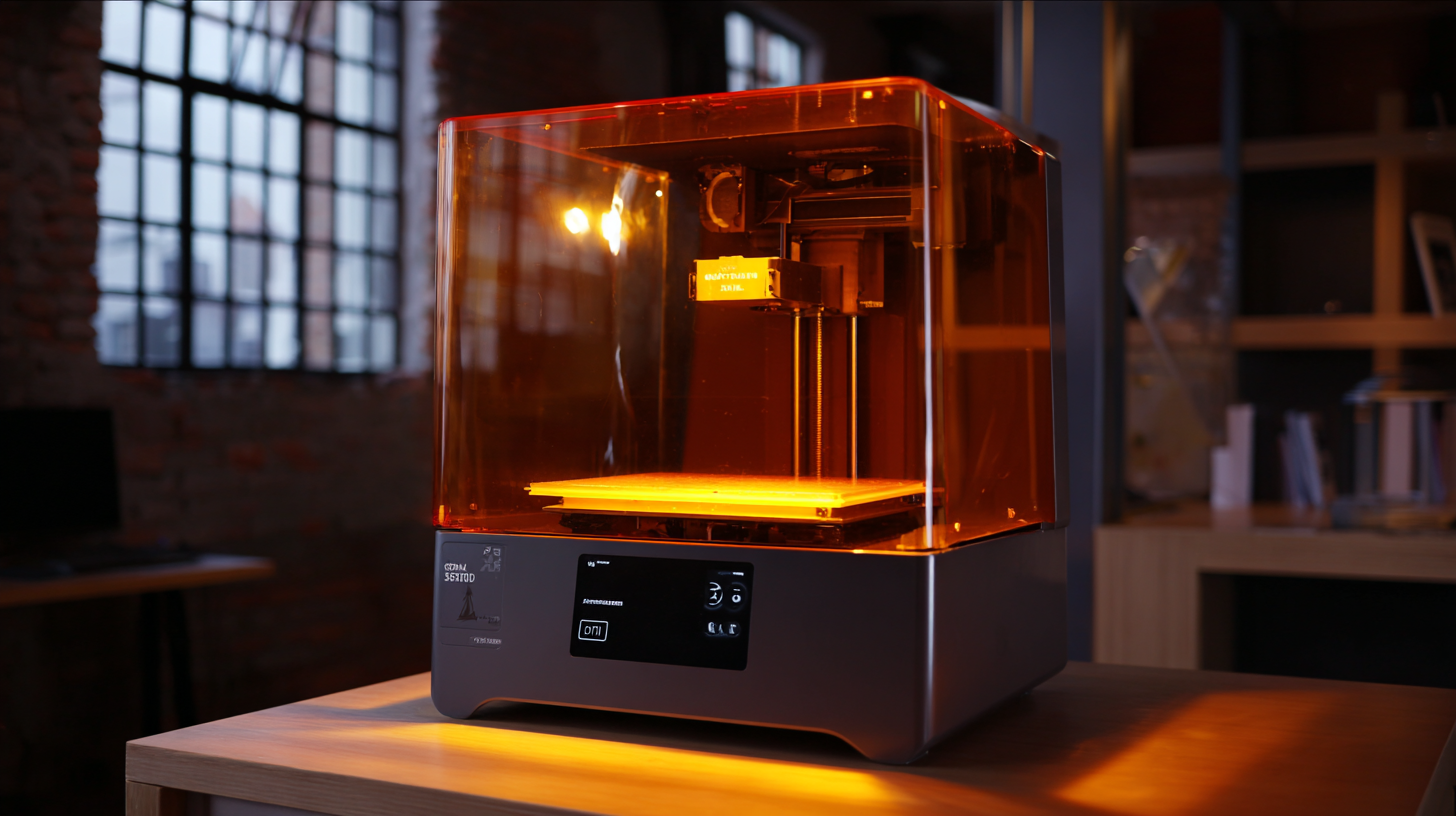

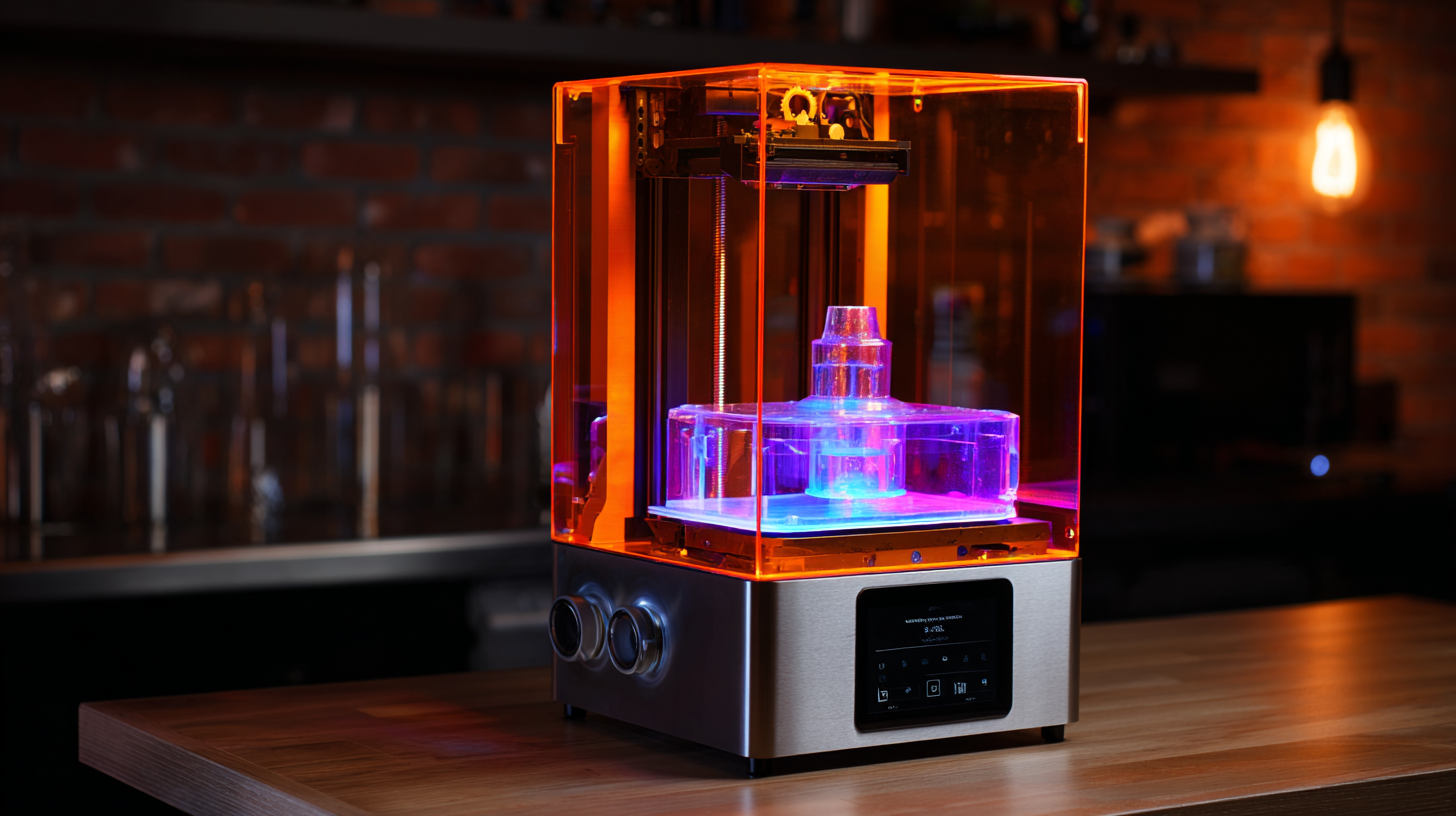

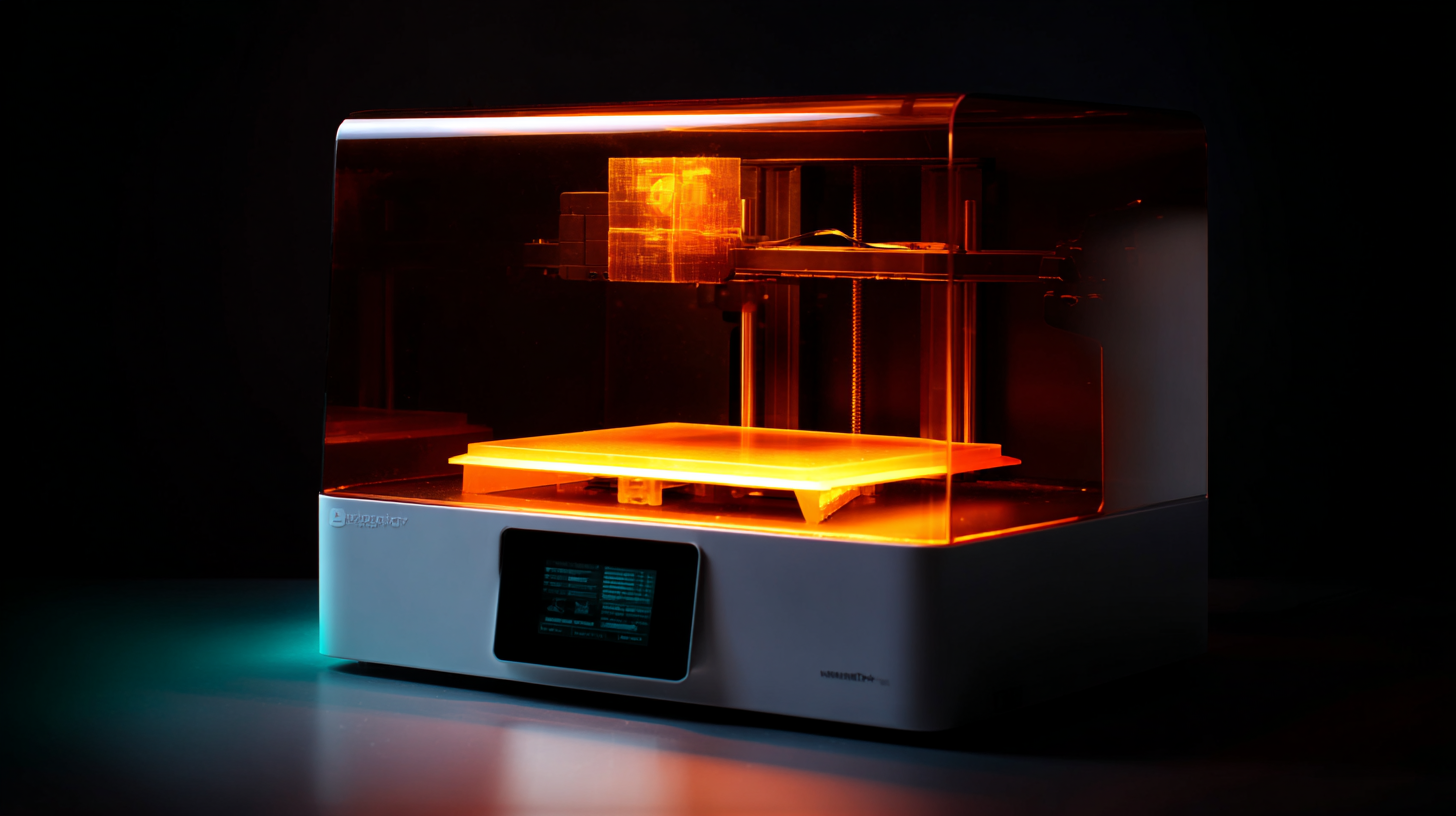

As we stand on the brink of a technological revolution, the future of manufacturing and design is being reshaped by innovations like DLP resin technology. The emergence of the DLP resin printer has opened up new avenues for rapid prototyping and intricate design, significantly enhancing the capabilities of 3D printing. Unlike traditional methods, DLP (Digital Light Processing) utilizes a digital light projector to cure liquid resin layer by layer, resulting in highly detailed and accurate prints. This process not only accelerates production times but also allows for the creation of complex geometries that were previously unimaginable.

As industries from aerospace to healthcare begin to embrace this technology, the potential applications of DLP resin printing continue to expand, underscoring its role as a transformative force in the future of manufacturing. In this exploration, we will delve deeper into the benefits and future prospects of DLP resin technology, illuminating why it is poised to become a cornerstone of modern fabrication.

Table of Contents

[Hide]

The Rise of DLP Resin Technology in 3D Printing: Market Trends and Projections

DLP (Digital Light Processing) resin technology is emerging as a transformative force in the 3D printing landscape. This innovative approach leverages light to cure liquid resin layer by layer, resulting in highly detailed and accurate prints. As manufacturers and designers increasingly seek rapid prototyping and customization, the speed and precision offered by DLP technology have led to its rising popularity. The market for DLP resin printers is projected to grow significantly, driven by advancements in materials and reductions in cost.

In recent years, a plethora of industries, from healthcare to automotive, have adopted DLP resin technology for its exceptional capabilities. Market trends suggest a strong shift toward environmentally friendly practices, spurring the development of sustainable resin materials. The versatility of DLP technology allows for the creation of intricate designs and complex geometries, which is particularly appealing for applications such as dental aligners and bespoke jewelry. With ongoing innovations and increasing accessibility, DLP resin technology is poised to redefine the future of 3D printing, enhancing both production efficiency and creative possibilities across various sectors.

Understanding the Advantages of DLP Over Traditional 3D Printing Methods

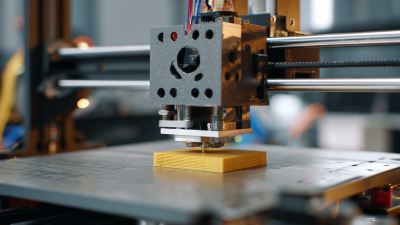

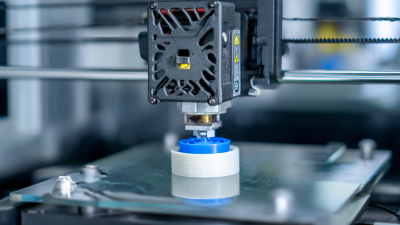

Digital Light Processing (DLP) technology is revolutionizing the 3D printing landscape by offering distinct advantages over traditional methods. One of the key benefits of DLP is its rapid printing speed, which significantly reduces the time required to create high-quality prints. Unlike conventional 3D printing techniques that layer materials one at a time, DLP cure resins layer by projecting an entire cross-section of the object at once, allowing for faster production without sacrificing precision.

Furthermore, DLP technology excels in achieving impressive resolution and detail, making it particularly suitable for applications in industries such as dental and jewelry design. The capability of DLP to produce intricate features at a micron level enhances the overall quality of the prints, catering to the demands for accuracy and aesthetics. As the technology continues to evolve, its potential in diverse sectors is becoming increasingly apparent, positioning DLP as a leading choice for both in-office and industrial printing needs.

3D Printing Technology Comparison: DLP vs. Traditional Methods

Key Applications of DLP Resin Printing in Various Industries: A Comprehensive Overview

DLP (Digital Light Processing) resin printing is revolutionizing various industries by enabling high-precision manufacturing. One of the most significant applications of DLP resin technology is in the dental field. Dental labs utilize this technology to create detailed models and dental prosthetics, allowing for quicker turnaround times and enhanced customization for patients. The ability to produce intricate designs with smooth surfaces makes DLP ideal for crafting crowns, bridges, and aligners that fit seamlessly.

DLP (Digital Light Processing) resin printing is revolutionizing various industries by enabling high-precision manufacturing. One of the most significant applications of DLP resin technology is in the dental field. Dental labs utilize this technology to create detailed models and dental prosthetics, allowing for quicker turnaround times and enhanced customization for patients. The ability to produce intricate designs with smooth surfaces makes DLP ideal for crafting crowns, bridges, and aligners that fit seamlessly.

Another impactful application of DLP resin printing is in the jewelry industry. The high resolution and rapid printing capabilities allow jewelers to create intricate designs that capture fine details, significantly reducing the prototyping time for new pieces. This technology supports the creation of molds for casting, enabling more intricate designs compared to traditional methods. Additionally, the medical sector is leveraging DLP resin for creating patient-specific implants and surgical guides, facilitating more personalized medical solutions that improve patient outcomes. Each of these applications highlights the versatility and significance of DLP resin printing across diverse fields, paving the way for innovation and efficiency.

Navigating Challenges in DLP Resin Technology: Quality, Speed, and Cost Factors

The advancement of DLP resin technology in 3D printing presents both opportunities and challenges. As the industry for 3D printing medical devices demonstrates rapid growth—projected to reach a staggering $6.9 billion by 2028, up from $2.7 billion in 2022 at a CAGR of 17.1%—the demand for high-quality, efficient printing solutions has never been more critical. DLP technology, renowned for its speed and precision, can significantly enhance the production of intricate medical devices, yet issues surrounding quality control and cost-effectiveness remain paramount.

Quality is a persistent concern in the realm of DLP printing, particularly as the market expands. The latest innovations, such as advancements in flexible DLP printing for sensors and actuators, showcase the potential to create specialized devices. However, achieving a balance between quality and speed often requires sophisticated resins that may come at a premium. With the introduction of more affordable industrial polymer printers, there is hope for improved accessibility without compromising on the quality of outputs. As professionals navigate these factors, the evolution of DLP resin technology will continue to shape the future of 3D printing across diverse applications.

Exploring the Future of 3D Printing with DLP Resin Technology

| Dimension | Value |

|---|---|

| Print Speed (mm/hour) | 50-300 |

| Resolution (microns) | 25-100 |

| Material Cost ($/liter) | 50-150 |

| Typical Layer Thickness (mm) | 0.025-0.1 |

| Post-Processing Time (minutes) | 30-120 |

| Durability (years) | 1-5 |

| User Skill Level | Beginner to Advanced |

Future Innovations in DLP Resin Formulations and Their Impact on 3D Printing

The future of 3D printing is poised for transformative advancements through the evolution of Digital Light Processing (DLP) resin formulations. As manufacturers continue to refine these materials, we can expect resins that not only enhance print quality but are also tailored for specific applications across various industries. Innovations such as biocompatible resins for medical devices or durable materials for aerospace components demonstrate the expanding versatility of DLP technology, ensuring that it meets the diverse needs of different sectors.

Moreover, we are witnessing a shift towards eco-friendly resin options, driven by increasing environmental awareness and regulatory pressures. Developments in sustainable materials, such as bio-based resins or recyclable formulations, are emerging to address the environmental impact of traditional 3D printing processes. This not only aligns with global sustainability goals but also offers opportunities for manufacturers to reduce their carbon footprint while maintaining high-performance standards. As DLP resin formulations continue to advance, they will undoubtedly play a crucial role in redefining the future landscape of 3D printing technology.

Related Posts

-

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

-

Unlocking the Future of Creativity with 3D Printers for Every Home

-

Exploring the Impact of Polymer 3D Printers at the 138th China Import and Export Fair 2025

-

Unlocking the Future Best 8K 3D Printer for Global Buyers

-

Mastering the Basics of Powder 3D Printing with Our Step by Step Guide

-

The Future of Creative Production with 3D Plastic Printers