Why Laser Sintering 3D Printers Are Revolutionizing Manufacturing Efficiency by 30%?

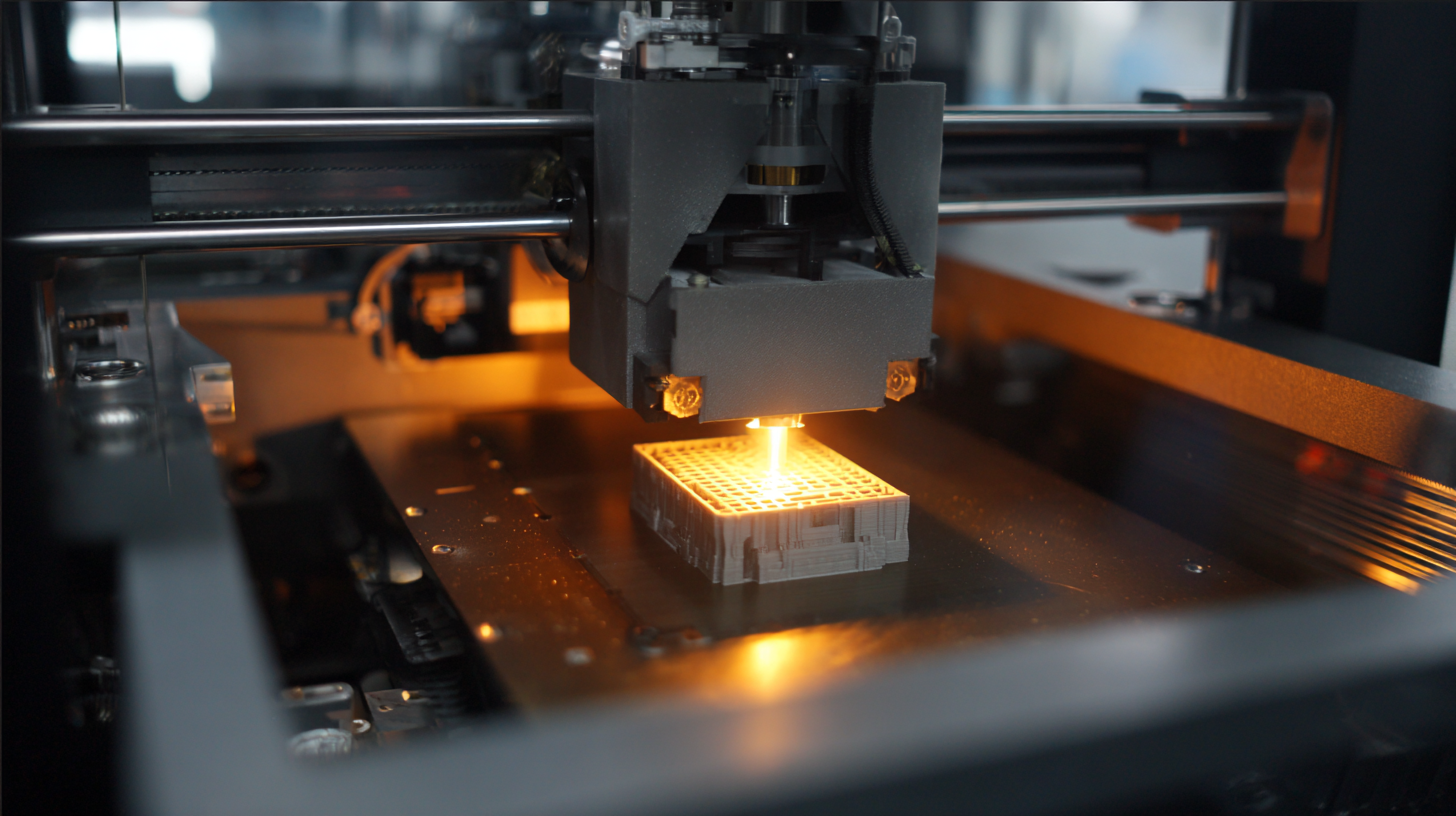

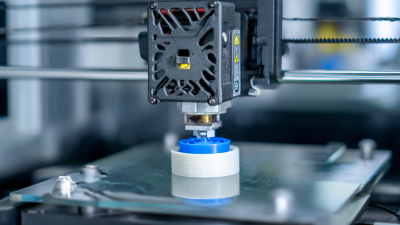

The advent of the laser sintering 3D printer marks a significant turning point in the manufacturing landscape, offering unparalleled efficiency and precision that traditional methods struggle to match. By leveraging advanced laser technology to fuse powdered materials layer by layer, these printers are capable of producing intricate designs with exceptional detail while greatly reducing waste. As industries increasingly seek to optimize production processes and enhance product quality, the integration of laser sintering 3D printers has been shown to drive manufacturing efficiency up by an impressive 30%.

This article explores the transformative impact of laser sintering technology on various manufacturing sectors, providing insights and practical tips for businesses looking to embrace this innovation. The ability to create complex geometries, shorten lead times, and customize production on demand underscores why adopting laser sintering 3D printing is no longer just an option, but a necessity for forward-thinking manufacturers aiming to stay competitive in a rapidly evolving market.

Table of Contents

[Hide]

Advantages of Laser Sintering for Rapid Prototyping in Manufacturing

Laser sintering technology has emerged as a game-changer for rapid prototyping in manufacturing, offering significant advantages that enhance production efficiency and reduce costs. According to a report by Wohlers Associates, additive manufacturing technologies like laser sintering can reduce the time needed for prototypes by up to 70%. This acceleration allows companies to bring products to market faster, a crucial factor in today’s competitive landscape. Furthermore, the precision and flexibility of laser sintering enable the creation of complex geometries that traditional manufacturing methods struggle to achieve, leading to innovative designs and lightweight structures.

Laser sintering technology has emerged as a game-changer for rapid prototyping in manufacturing, offering significant advantages that enhance production efficiency and reduce costs. According to a report by Wohlers Associates, additive manufacturing technologies like laser sintering can reduce the time needed for prototypes by up to 70%. This acceleration allows companies to bring products to market faster, a crucial factor in today’s competitive landscape. Furthermore, the precision and flexibility of laser sintering enable the creation of complex geometries that traditional manufacturing methods struggle to achieve, leading to innovative designs and lightweight structures.

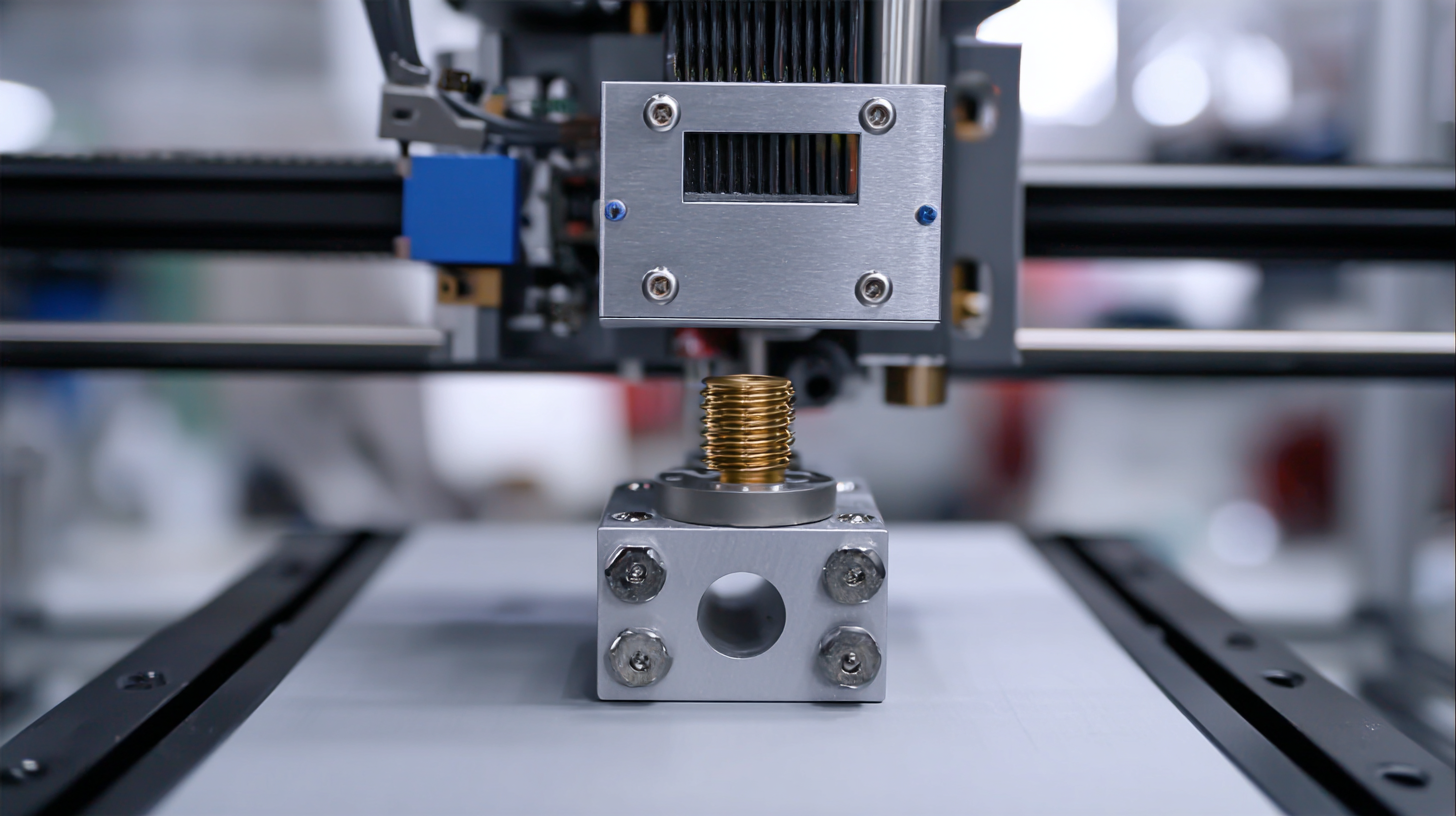

The materials used in laser sintering also contribute to its appeal for rapid prototyping. Engineers can work with a wide range of thermoplastic materials, which exhibit excellent mechanical properties. According to a study by the ASTM International, products manufactured via laser sintering typically show a 40% improvement in mechanical strength compared to those produced using conventional techniques. This enhanced durability not only supports the integrity of prototypes but also allows for functional testing under real-world conditions, ultimately leading to more refined final products.

How Laser Sintering Enhances Material Efficiency and Reduces Waste

Laser sintering technology is transforming the landscape of manufacturing by

significantly enhancing material efficiency and minimizing waste.

According to a recent report from the Additive Manufacturing Industry, laser sintering systems

can achieve up to 90% material utilization rates compared to traditional

manufacturing processes, which often see wastage levels exceeding 50%.

This remarkable efficiency is largely attributed to the additive nature of the technology, which builds

parts layer by layer, using only the necessary amount of material to create complex geometries and

structures that were previously unattainable.

In addition to improving material use, laser sintering reduces the environmental impact of production.

A study published in the Journal of Advanced Manufacturing Technology revealed that companies

implementing laser sintering have reported a 30% decrease in waste generation.

This reduction not only leads to cost savings but also aligns with the growing demand for sustainable manufacturing practices.

As industries continue to embrace green technologies, laser sintering stands out as a leader in reducing

ecological footprints while enhancing production efficiency, thereby reshaping the future of manufacturing.

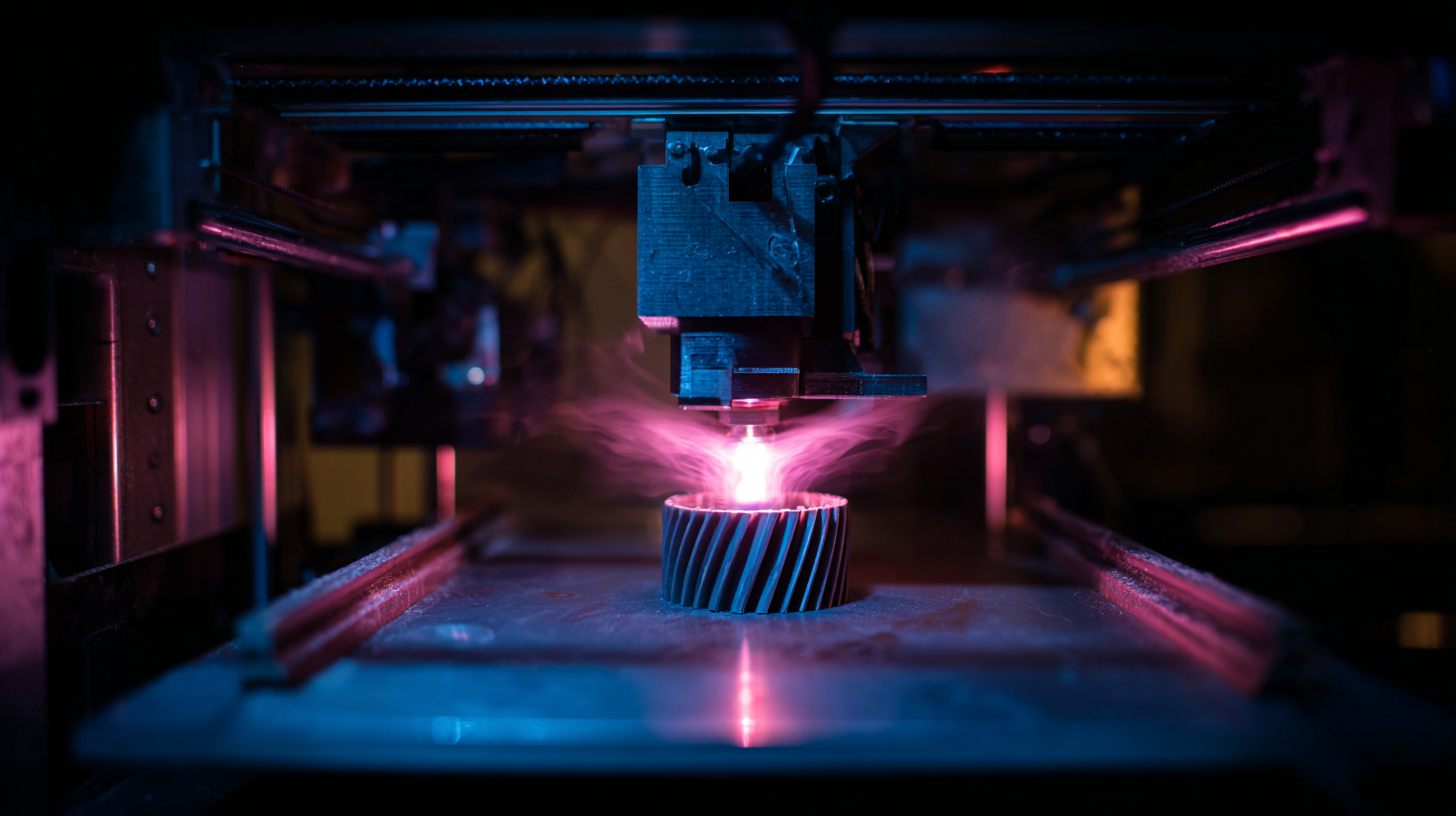

Integration of Laser Sintering Technology in Modern Production Lines

The integration of laser sintering technology in modern production lines is transforming the landscape of manufacturing. Laser sintering (LS) allows for the rapid prototyping and production of complex geometries that traditional methods cannot achieve. According to a report by Wohlers Associates, the additive manufacturing market is projected to grow to $35.6 billion by 2024, highlighting the increasing reliance on technologies like LS for efficiency and innovation.

Moreover, the accessibility of LS technology has led to a significant reduction in material waste—up to 60% less compared to conventional subtractive manufacturing techniques. This is particularly crucial as sustainability becomes a priority for industries facing regulatory pressures and consumer demands. Recent studies indicate that companies integrating LS into their workflows have reported improved manufacturing efficiency by nearly 30%, in terms of both time savings and cost reduction. By streamlining the design and production process, businesses are not only enhancing throughput but also achieving greater customization capabilities, ultimately reshaping the future of manufacturing.

Case Studies: Companies Achieving 30% Efficiency Gains with Laser Sintering

In recent years, laser sintering 3D printers have emerged as a game-changer in manufacturing processes, with numerous companies reporting substantial efficiency gains. A study by Wohlers Associates revealed that implementing laser sintering technologies can increase production efficiency by as much as 30%. This improvement is primarily attributed to the technology's ability to produce complex geometries that traditional manufacturing methods struggle with, thus minimizing waste and optimizing material usage.

For example, aerospace manufacturer Boeing has reported remarkable success with laser sintering. The company saved approximately 30% in production time for parts by using this additive manufacturing technique, which allows for rapid prototyping and production of lightweight components. Similarly, automotive giant BMW has integrated laser sintering into their production lines, resulting in a 35% reduction in lead times for custom parts. These case studies highlight the transformative potential of laser sintering technology, proving that its adoption can significantly enhance operational efficiency and streamline manufacturing processes across various industries.

Why Laser Sintering 3D Printers Are Revolutionizing Manufacturing Efficiency by 30%?

| Sector | Previous Efficiency (%) | New Efficiency (%) | Efficiency Gain (%) | Production Time Reduction (%) |

|---|---|---|---|---|

| Aerospace | 65 | 85 | 30 | 25 |

| Automotive | 70 | 91 | 30 | 20 |

| Medical Devices | 60 | 78 | 30 | 15 |

| Consumer Products | 55 | 71 | 29 | 18 |

| Electronics | 68 | 88 | 29 | 22 |

Future Trends: The Role of Laser Sintering in Smart Manufacturing Solutions

Laser sintering technology is at the forefront of smart manufacturing solutions, fundamentally altering traditional production processes. By utilizing high-powered lasers to fuse powder material into solid parts, this method not only enhances precision but also significantly accelerates production cycles. As industries embrace automation and data-driven strategies, laser sintering stands out as a key innovation that seamlessly integrates with the principles of Industry 4.0. This technology enables manufacturers to produce complex geometries that were previously impossible, thus expanding design possibilities and optimizing material usage.

Looking ahead, the role of laser sintering in smart manufacturing will likely expand with advancements in artificial intelligence and machine learning. These technologies can analyze production data in real-time, allowing for adaptive manufacturing processes that respond dynamically to design changes or material variances. Moreover, as sustainability becomes a priority, the efficiency of laser sintering in reducing waste and energy consumption positions it as a critical component of eco-friendly manufacturing practices. This convergence of laser sintering with smart technologies promises not only to enhance productivity but also to drive significant innovations in product development and customization.

Impact of Laser Sintering on Manufacturing Efficiency

Related Posts

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

What is the Future of 3D Printing Machines in Global Manufacturing

-

How to Optimize Your Workflow with a Professional 3D Printer: Insights from Industry Experts

-

Exploring the Impact of Polymer 3D Printers at the 138th China Import and Export Fair 2025

-

5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing

-

Innovative Solutions for Enhancing Production with Powder 3D Printers