Top 5 Laser Sintering 3D Printers You Need to Know for High Quality Prototyping

In the rapidly evolving landscape of additive manufacturing,

laser sintering 3D printers have emerged as pivotal tools for high-quality prototyping.

As industry experts highlight the advantages of this technology, renowned figure Dr. Emily Turner,

a leading researcher in 3D printing innovations, states, “The precision and efficiency of laser sintering 3D printers

make them indispensable for creating complex prototypes that meet the demands of modern engineering.”

This sentiment resonates with many within the industry, underscoring the need for effective solutions in

product development.

laser sintering 3D printers have emerged as pivotal tools for high-quality prototyping.

As industry experts highlight the advantages of this technology, renowned figure Dr. Emily Turner,

a leading researcher in 3D printing innovations, states, “The precision and efficiency of laser sintering 3D printers

make them indispensable for creating complex prototypes that meet the demands of modern engineering.”

This sentiment resonates with many within the industry, underscoring the need for effective solutions in

product development.

As we approach 2025, it becomes essential to explore the top laser sintering 3D printers that are transforming the way businesses and designers approach prototyping. These machines not only provide unparalleled accuracy but also enhance the material properties of prototypes, facilitating faster time-to-market cycles. In this context, understanding the cutting-edge technologies and capabilities of the leading laser sintering 3D printers will empower practitioners to make informed decisions in their creative processes. By examining the top contenders in this category, we aim to illuminate the future possibilities of laser sintering technology in high-quality prototype production.

Table of Contents

[Hide]

Key Features to Look for in High-Quality Laser Sintering 3D Printers

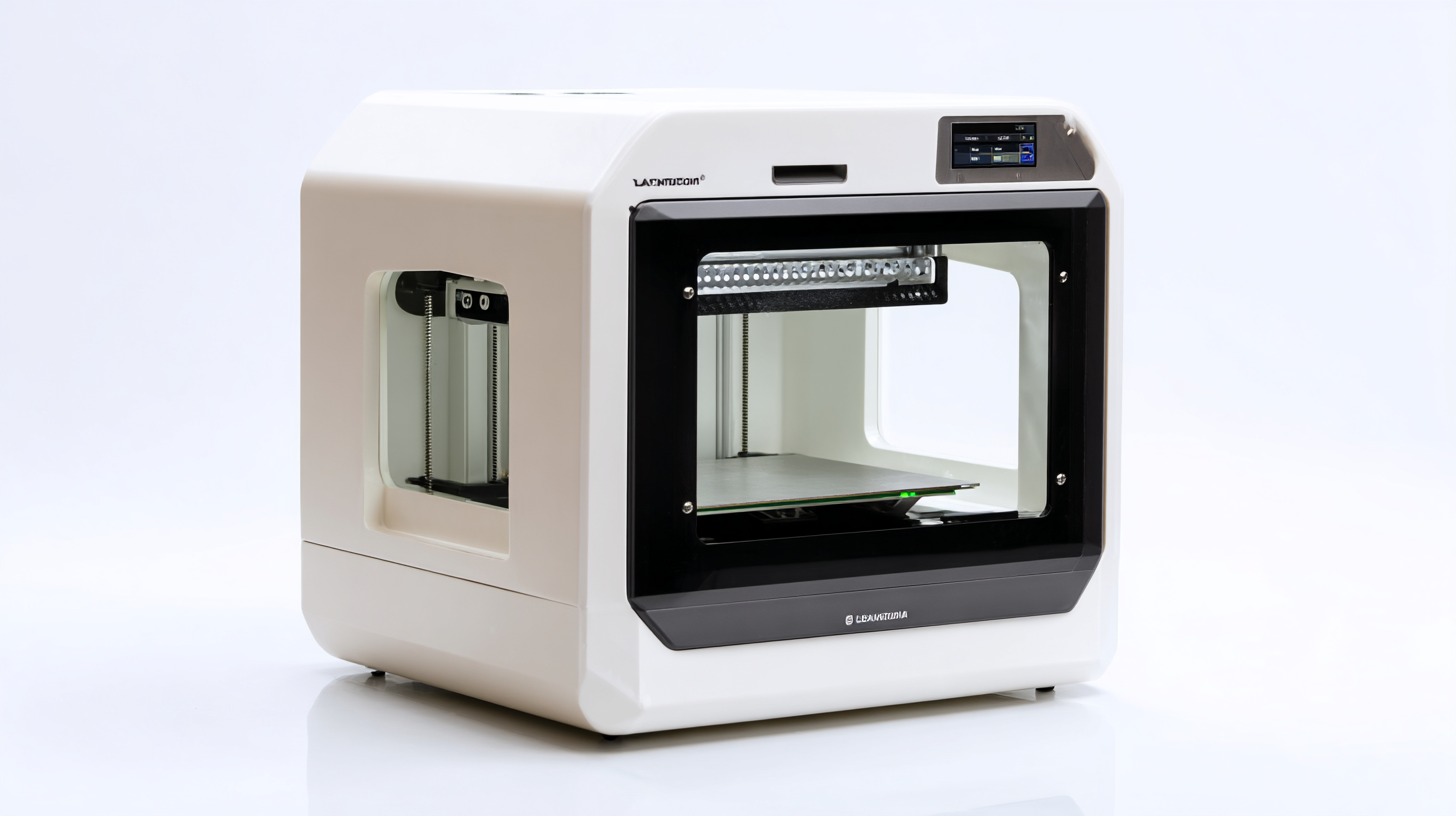

When selecting high-quality laser sintering 3D printers for prototyping, several key features should be at the forefront of your considerations. First, the printing speed and layer thickness play a crucial role in the efficiency and quality of the final product. Printers that offer adjustable layer thickness allow for fine-tuning based on the specific requirements of the prototype, resulting in enhanced detail and surface finish.

Another vital aspect is the material compatibility of the printer. A broader range of materials, especially those with high-performance characteristics such as heat resistance and mechanical strength, allows for greater versatility in prototyping applications. Moreover, advanced features like temperature control, and the ability to handle multi-material printing can greatly impact the quality and functionality of the prototypes produced. Lastly, user-friendly software integration and remote monitoring capabilities enhance the overall user experience, making the printing process smoother and more efficient.

Innovative Technologies Reshaping Prototyping in 2025

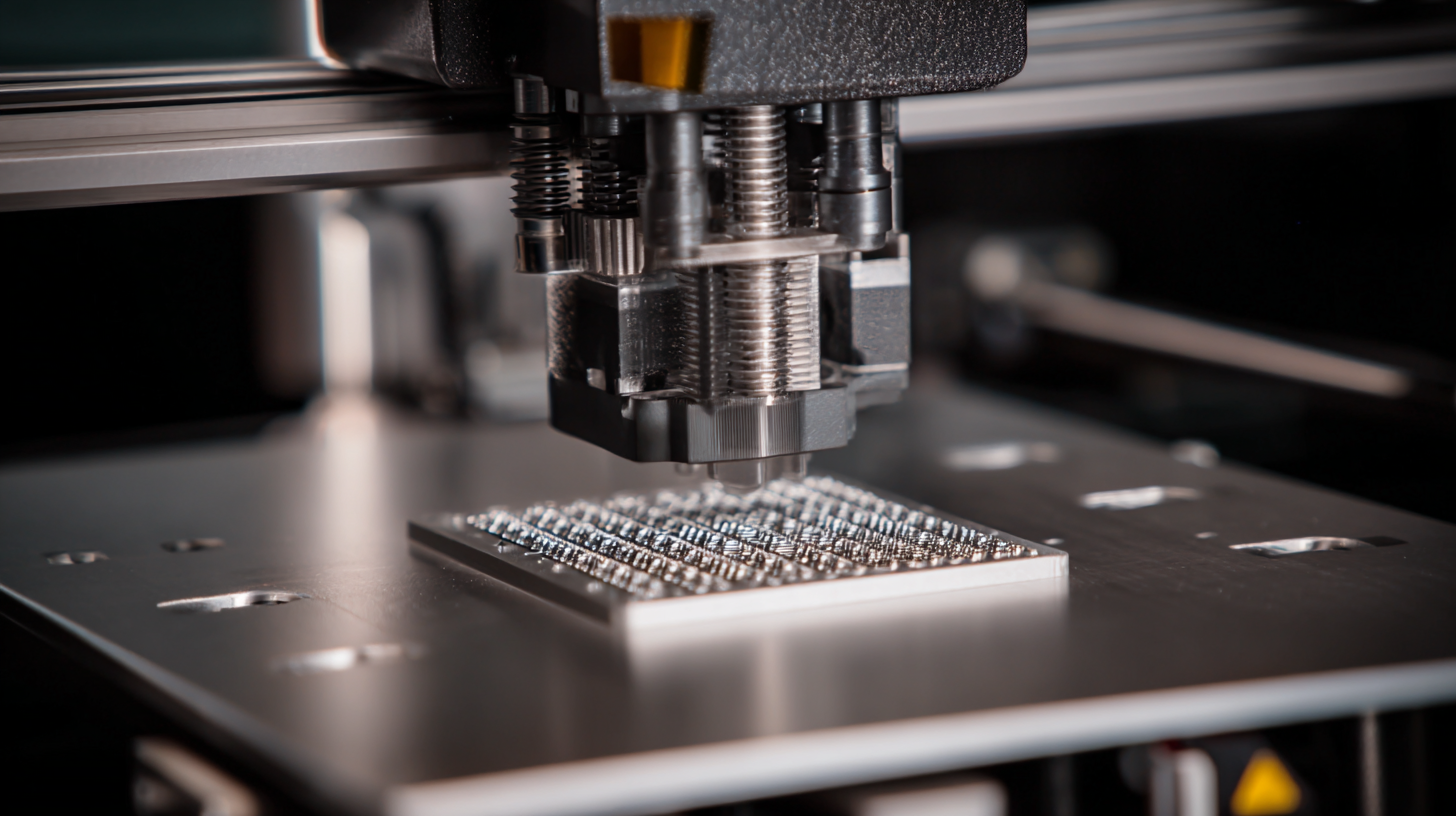

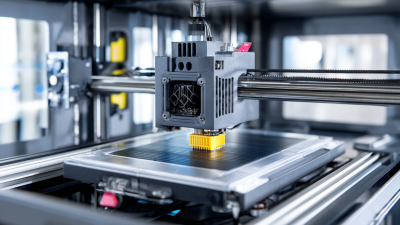

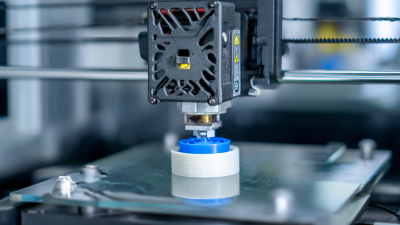

The landscape of prototyping is set to undergo a significant transformation by 2025, thanks to innovative technologies that enhance the capabilities of laser sintering 3D printers. These advanced printers utilize high-powered lasers to fuse powdered materials layer by layer, resulting in high-precision prototypes that meet stringent quality standards. As industries seek faster turnaround times and cost-efficiency, these innovations are paving the way for more complex designs and functionalities that were previously unattainable, thereby revolutionizing product development processes.

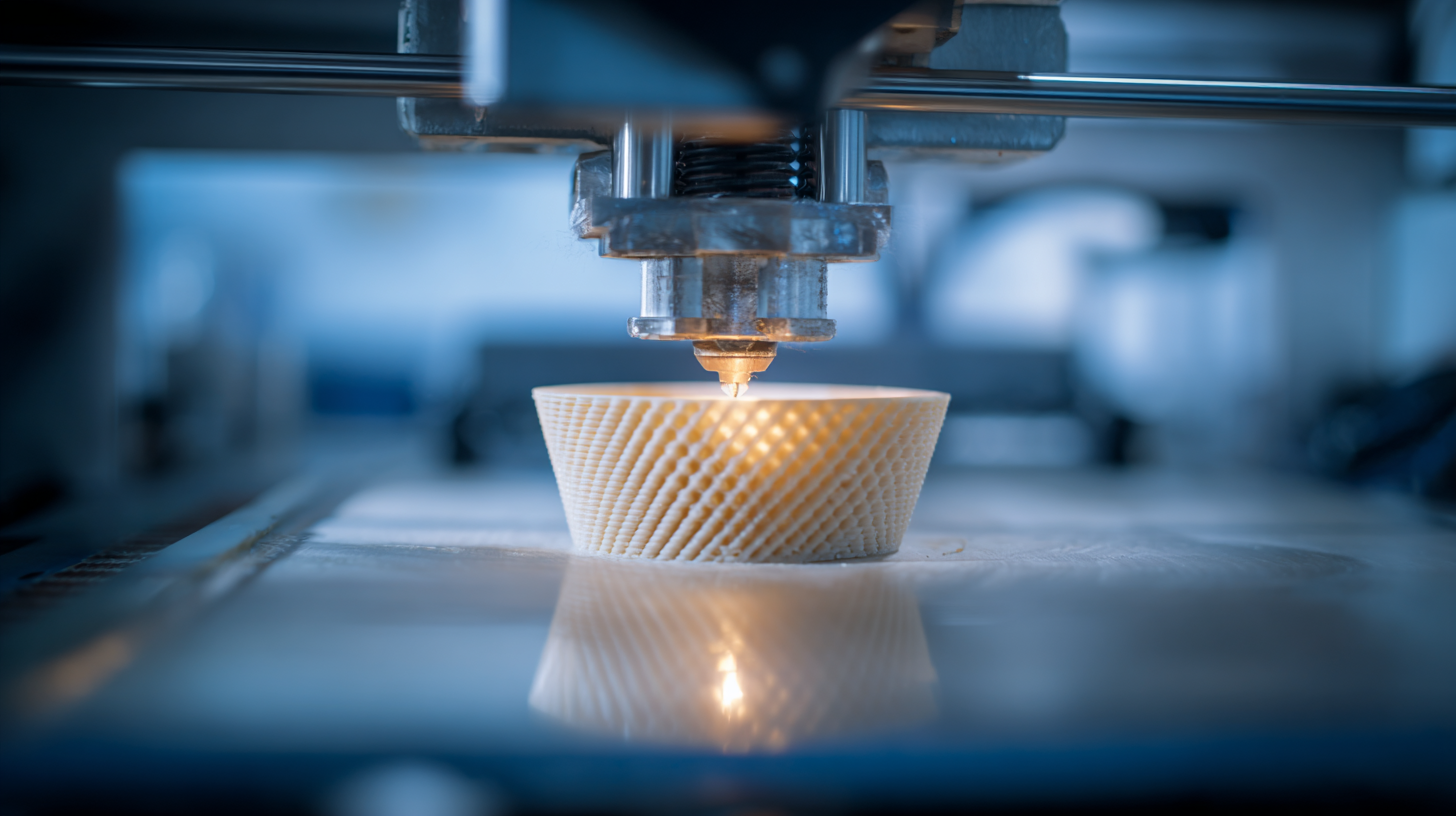

As laser sintering technology evolves, we can expect to see improvements in various aspects, including material versatility, print speed, and user-friendly interfaces. Manufacturers are now exploring new materials beyond traditional plastics and metals, enabling the creation of prototypes with superior mechanical properties and unique characteristics. Additionally, advancements in software and automation are streamlining the design-to-print workflow, making high-quality prototyping more accessible than ever. These trends highlight a pivotal shift in how products are conceived and developed, ultimately driving industry growth and fostering creativity in design.

Top 5 Laser Sintering 3D Printers for High Quality Prototyping

Comparative Analysis of the Top 5 Laser Sintering 3D Printers

Laser sintering technology has significantly advanced, becoming a cornerstone for high-quality prototyping in various industries, from aerospace to healthcare. In a recent report by the Wohlers Associates, the market for additive manufacturing is projected to reach $35.4 billion by 2024, indicating the growing reliance on precision and efficiency offered by laser sintering machines. These printers utilize a high-powered laser to fuse powdered materials, resulting in intricately designed parts that exhibit exceptional mechanical properties.

When comparing the top five laser sintering 3D printers, factors such as build volume, layer resolution, and materials compatibility are critical. For instance, the EOS P 500 boasts a build volume of 700 x 380 x 400 mm, alongside a layer thickness as fine as 60 microns, making it suitable for producing complex geometries with minimal post-processing. Meanwhile, the Sinterit Lisa capabilities highlight its compact design while still delivering high-quality prototypes, making it ideal for small-scale operations. Reports predict that advancements in these technologies will continue to improve efficiency, allowing industries to reduce production times and costs significantly.

Real-World Applications of Laser Sintering in Rapid Prototyping

Laser sintering is a groundbreaking technique in the realm of 3D printing, significantly enhancing the efficiency and quality of rapid prototyping across various industries. One of its most compelling applications is in the medical field, where customized implants and models are produced swiftly, allowing for better patient outcomes and improved recovery times. This innovation enables medical professionals to move from concept to reality faster than ever, ultimately transforming how medical devices are designed and produced.

Tips for utilizing laser sintering in prototyping:

- Ensure that your design software supports the complex geometries possible with this technology.

- Utilize materials specifically designed for laser sintering to enhance the performance and durability of your prototypes.

- Engage with a professional service experienced in additive manufacturing to streamline the process, allowing for quick iterations and adjustments based on real-world testing.

Industries such as aerospace and automotive are equally benefiting from laser sintering, as it allows for the creation of lightweight and high-strength components that meet rigorous standards. This capability not only boosts the effectiveness of products but also contributes to more sustainable manufacturing practices. Leveraging laser sintering in these sectors exemplifies the potential for rapid prototyping to drive innovation and efficiency in modern product development.

Cost Considerations and ROI for Investing in Laser Sintering Printers

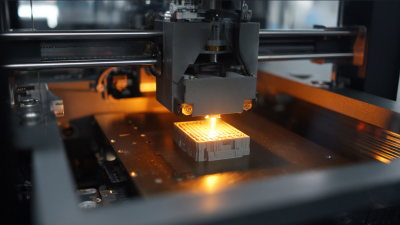

Investing in laser sintering 3D printers involves weighing both upfront and long-term cost considerations. The initial purchase price of these high-quality machines can be substantial, often ranging from tens to hundreds of thousands of dollars. However, it’s essential to consider this expense as a strategic investment rather than a mere expenditure. Factors such as maintenance costs, material expenses, and operational efficiency play significant roles in the overall financial landscape. By conducting a thorough cost-benefit analysis, businesses can better understand the potential return on investment (ROI).

In addition to direct costs, organizations should evaluate the value of enhanced prototyping capabilities that laser sintering printers provide. These machines offer unparalleled precision and the ability to produce complex geometries, resulting in higher quality prototypes that reduce the need for multiple iterations. This efficiency not only saves time but also lowers the risk of costly errors during the production process. Ultimately, while the initial investment in laser sintering technology may be high, the long-term savings and increased production capabilities can significantly outweigh the costs, leading to a favorable ROI for companies committed to innovation and excellence in prototyping.

Top 5 Laser Sintering 3D Printers for High Quality Prototyping

| Model | Build Volume (mm) | Layer Thickness (µm) | Material Compatibility | Approx. Cost (USD) | ROI (Years) |

|---|---|---|---|---|---|

| Model A | 250 x 250 x 300 | 50 | Nylon, TPU | $80,000 | 3 |

| Model B | 300 x 300 x 400 | 60 | PA, PA-CF | $120,000 | 4 |

| Model C | 400 x 400 x 500 | 40 | Nylon, Alumide | $150,000 | 5 |

| Model D | 350 x 350 x 300 | 50 | Nylon, Polycarbonate | $95,000 | 3.5 |

| Model E | 500 x 500 x 600 | 30 | Nylon, TPU, Glass-filled | $200,000 | 6 |

Related Posts

-

Why Laser Sintering 3D Printers Are Revolutionizing Manufacturing Efficiency by 30%?

-

Unlocking the Future of Creativity with 3D Printers for Every Home

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

What is the Future of 3D Printing Machines in Global Manufacturing

-

How to Optimize Your Workflow with a Professional 3D Printer: Insights from Industry Experts

-

Exploring the Impact of Polymer 3D Printers at the 138th China Import and Export Fair 2025